Here are some keynotes to keep in mind when performing 5G position welding:

- The 5G position is a challenging welding position that requires a combination of uphill and downhill welding techniques.

- Proper preparation of the work area and the metal surface is critical to achieving a strong and consistent weld.

- Using the appropriate equipment, such as a welding machine, welding torch, filler metal, and shielding gas, is essential to creating a successful weld.

- Maintaining a consistent arc length, using the correct amperage setting for the material, and choosing the appropriate filler metal are key techniques for successful 5G position welding.

- Welders should always practice proper safety measures, including wearing appropriate personal protective equipment, such as welding gloves, goggles, and a helmet with a face shield, and ensuring proper ventilation in the welding area to avoid inhaling harmful fumes.

By following these keynotes, welders can successfully perform 5G position welding and achieve strong and consistent welds.

Keynotes

According to a report by MarketsandMarkets, the global welding industry is projected to reach $27.22 billion by 2026, with a compound annual growth rate (CAGR) of 4.3% from 2021 to 2026. In this industry, 5G welding position is a widely used technique for welding large and heavy pipes that cannot be rotated.

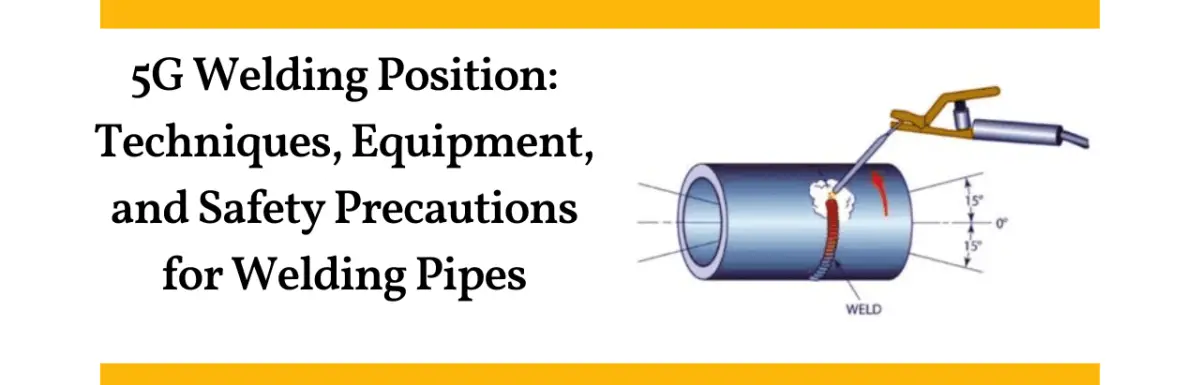

The 5G welding position involves fixing the pipe horizontally and welding from the side of the pipe. To create a strong and consistent weld, the welder needs to position themselves at a 45-degree angle to the pipe and use both uphill and downhill welding techniques.

Before beginning the welding process, it is crucial to clean the welding area thoroughly to prevent any contaminants from weakening the weld. Welders should also select the appropriate welding equipment and materials, such as the welding machine, filler metal, and shielding gas, based on the specific requirements of the job.

It is important to note that welding is a hazardous process that can have serious health and safety risks. The Occupational Safety and Health Administration reports that welding fumes can cause respiratory problems and other health issues. Therefore, welders should always wear appropriate personal protective equipment (PPE) such as welding gloves, goggles, and a helmet with a face shield. They should also ensure proper ventilation in the welding area to minimize exposure to harmful fumes.

What is 5G Welding Position?

The 5G welding position is a technique used in welding pipes that are too large or heavy to be rotated. In this position, the pipe is fixed horizontally, and the welder welds from the side of the pipe while positioned at a 45-degree angle. The 5G welding position requires the use of both uphill and downhill welding techniques to create a strong and consistent weld. It is widely used in industries such as oil and gas, construction, and manufacturing. Proper safety precautions, including the use of personal protective equipment and proper ventilation, should always be taken when welding in the 5G position.

Benefits of 5G Welding

The 5G welding position offers several benefits, including:

- Accessibility: The 5G position allows welders to access areas of the pipe that may be difficult to reach using other welding positions.

- Efficiency: Welding pipes in the 5G position can be more efficient than other welding positions because the pipe does not need to be rotated.

- Versatility: The 5G welding position can be used on pipes of various sizes and shapes, making it a versatile technique for welding pipes.

- High-quality welds: When performed correctly, the 5G welding position can produce high-quality welds that are strong and consistent.

- Reduced distortion: Welding in the 5G position can result in less distortion of the pipe because the heat is distributed more evenly.

Overall, the 5G welding position is a reliable and widely used technique for welding pipes in various industries. Its benefits make it an attractive option for welding professionals looking to achieve high-quality and efficient welds.

Necessary Equipment and Supplies for 5G Position

The following are necessary equipment and supplies required for a welder working in the 5G position:

- Welding machine: A welding machine is essential for welding in the 5G position. Welders must choose a machine that is suitable for the specific type of welding required and has enough power to handle the job.

- Welding accessories: Welding accessories such as welding torches, cables, and clamps are necessary for welding in the 5G position.

- Filler metal: Filler metal is used to fill the gap between the two pipes being welded. The type of filler metal used will depend on the specific job requirements.

- Shielding gas: Shielding gas is used to protect the molten metal from the atmosphere, preventing it from oxidizing and becoming weaker.

- Metal prep equipment: This includes tools such as grinders, wire brushes, and sandpaper, which are used to prepare the metal surfaces for welding.

- Safety gear and protective clothing: Welding in the 5G position can be hazardous, so it is essential to wear appropriate personal protective equipment (PPE) such as welding gloves, goggles, and a helmet with a face shield.

- Molten metal supplies: Welders must have the necessary supplies to manage the molten metal during the welding process. This includes items such as metal buckets, slag hammers, and chipping hammers.

By having the necessary equipment and supplies, welders can work safely and efficiently in the 5G position to create strong and consistent welds.

How to Set Up the Welder for 5G Position

Here are the steps to set up a welder for the 5G position:

- Prepare the work area: Ensure that the work area is clean, dry, and free from any debris or flammable materials that could be hazardous. Additionally, ensure that the work area is properly ventilated to avoid inhaling any harmful fumes.

- Assemble the machine and attachments: Assemble the welding machine and attach the appropriate accessories, such as the welding torch and cables.

- Adjust the voltage and amperage settings as needed: Adjust the voltage and amperage settings on the welding machine based on the specific job requirements. The recommended settings can be found in the welding manual or provided by the welding supervisor.

- Connect the ground clamp to the workpiece: Connect the ground clamp to the workpiece to ensure a stable electrical connection between the machine and the workpiece.

- Begin filling in the joint with molten metal: Begin filling in the joint with molten metal, using a combination of uphill and downhill welding techniques to create a strong and consistent weld. Be sure to follow the proper welding technique and use the appropriate filler metal and shielding gas.

It is important to note that welding in the 5G position can be a challenging task that requires practice and experience. Proper safety precautions should always be taken, including the use of personal protective equipment and ensuring proper ventilation in the work area.

Techniques for Successful 5G Position Welding

Here are some techniques that can help in achieving successful 5G position welding:

- Use the correct technique: The 5G position requires a combination of uphill and downhill welding techniques to create a strong and consistent weld. The uphill technique is used for the root pass, while the downhill technique is used for the fill and cap passes. Welders should practice and master these techniques to ensure a successful weld.

- Use a low amperage setting for thin materials: When welding thin materials, it is important to use a low amperage setting to avoid burning through the metal. This will help maintain the integrity of the joint and prevent any weakening or cracking.

- Maintain a consistent arc length: Maintaining a consistent arc length is critical to achieving a strong and consistent weld. Welders should keep the arc length within the recommended range and adjust it as needed throughout the welding process.

- Clean the metal surface: Before beginning the welding process, it is important to clean the metal surface thoroughly to remove any dirt, oil, or other contaminants that can weaken the weld. Welders can use a wire brush, sandpaper, or grinder to clean the surface.

- Use the appropriate filler metal: Using the appropriate filler metal is essential to creating a strong and durable weld. The filler metal should be compatible with the base metal and the specific welding process being used.

By following these techniques, welders can achieve successful 5G position welding with strong and consistent welds. It is also important to practice safe welding practices and use appropriate personal protective equipment to prevent any potential hazards.

Final Talk

In conclusion, 5G welding position refers to a horizontal-fixed position of the pipe, commonly used for welding large or heavy pipes that cannot be rotated. While it can be a challenging welding position, using the appropriate equipment, techniques, and safety measures can help welders achieve strong and consistent welds. It is essential to properly prepare the work area and metal surface, use the correct amperage setting and filler metal, and maintain a consistent arc length. Following these guidelines and practicing safe welding practices can help ensure successful 5G position welding and prevent potential hazards.