Table of Content

What is a left handed drill bit?

Left-handed drill bits (aka reverse thread drill bits) are different types of drill bits with flutes twisted in the opposite direction of the conventional drill bits. Machinists or technicians use them for specialized jobs like removing broken screws or nuts.

Difference between left and right hand drill bits

You may wonder the difference between a left-handed drill bit and a right-handed drill bit.

Most twist drill bits we see or use often are right-handed. These right-handed drill bits have flutes that twist right-handed or clockwise. They are designed to cut when rotated clockwise from the rear of the bit toward the point. On the contrary, a different type of drill bit exists, known as a left-handed drill bit. When viewed from the back, left twist drill bits have flutes that twist in a left-handed or counterclockwise direction.

Read this blog post about drill bits that are interchangeable between brands.

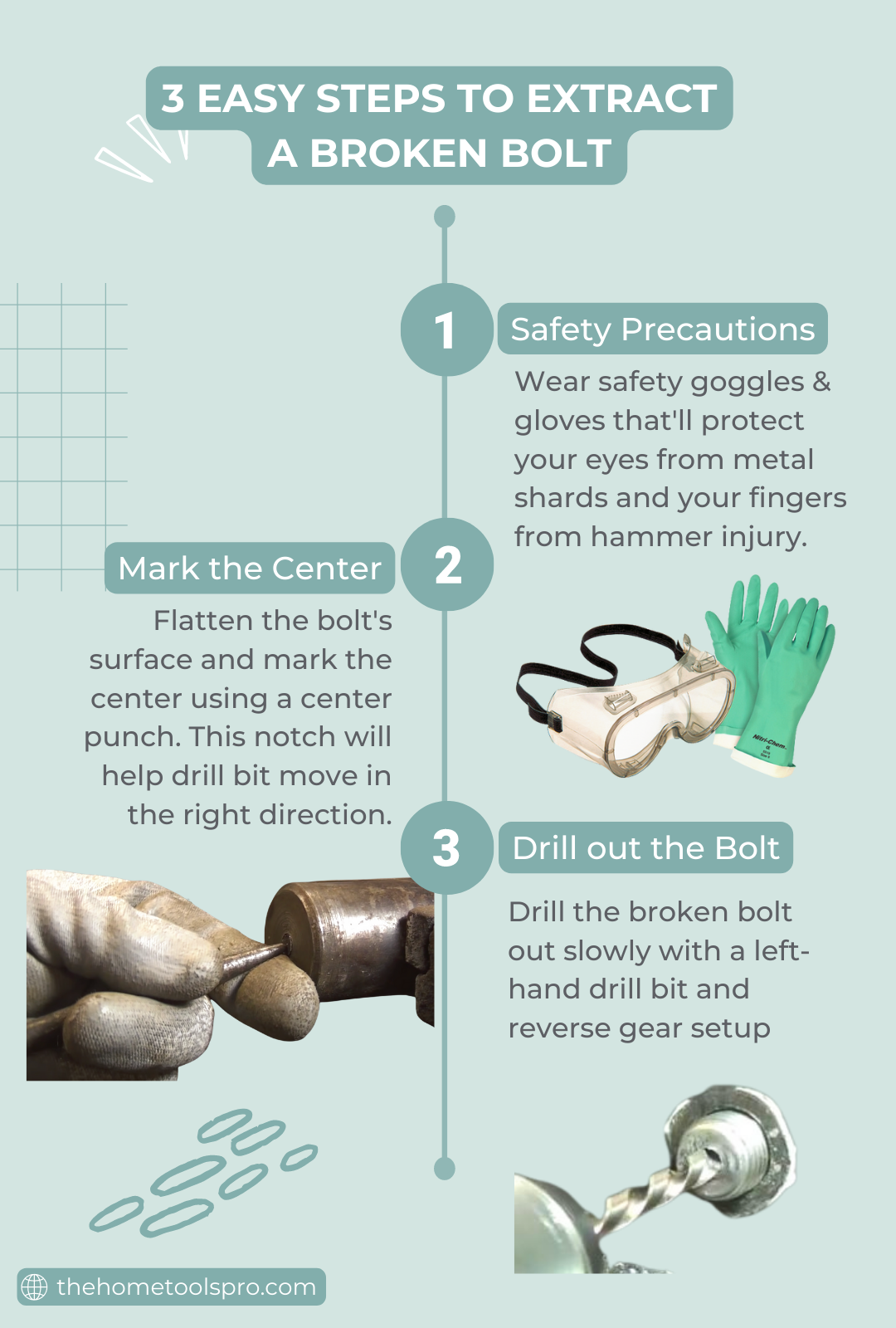

How to use left handed drill bit to remove a broken bolt

Those of you who have made your hands dirty with metal works (at least a little bit) will agree that a broken bolt stuck in its place is very annoying. It’s never easy to remove, but it’s possible with the right tools and methods. There are several ways to extract a broken bolt, but today, I will drill it out using a left handed drill bit. Read till the end to know in 3 easy steps how to use a left hand drill bit to remove a broken bolt yourself!

The tools you are going to need to remove bolt using left drill bit:

The first thing is first. You will need a few standard tools and equipment to accomplish the job. They are the following:

- A drilling machine with reversible gear (preferably a cordless one for easy handling)

- A proper-sized left-hand drill bit (the diameter should be less than the stuck bolt)

- File or grinder

- Center punch (automatic or manual)

- Hammer

- Thread cutting oil or lubricant

- Safety glasses

- Safety gloves

- Screw or bolt extractor or Easyout (optional)

I hope you have already gathered all the required tools…let’s jump right into the first step.

Step 1: Safety Precautions

Safety always comes first. Since you will be drilling into metal, metal shards could fly around. These metal shards or chips can strike your eyes anytime. Wear your safety glasses; you won’t get hurt by any of the metal shards.

Besides, you will need to hit the center punch with the hammer and hold it with your fingers. There is a risk of hitting the fingers with the hammer accidentally. So, wearing safety gloves will protect your fingers.

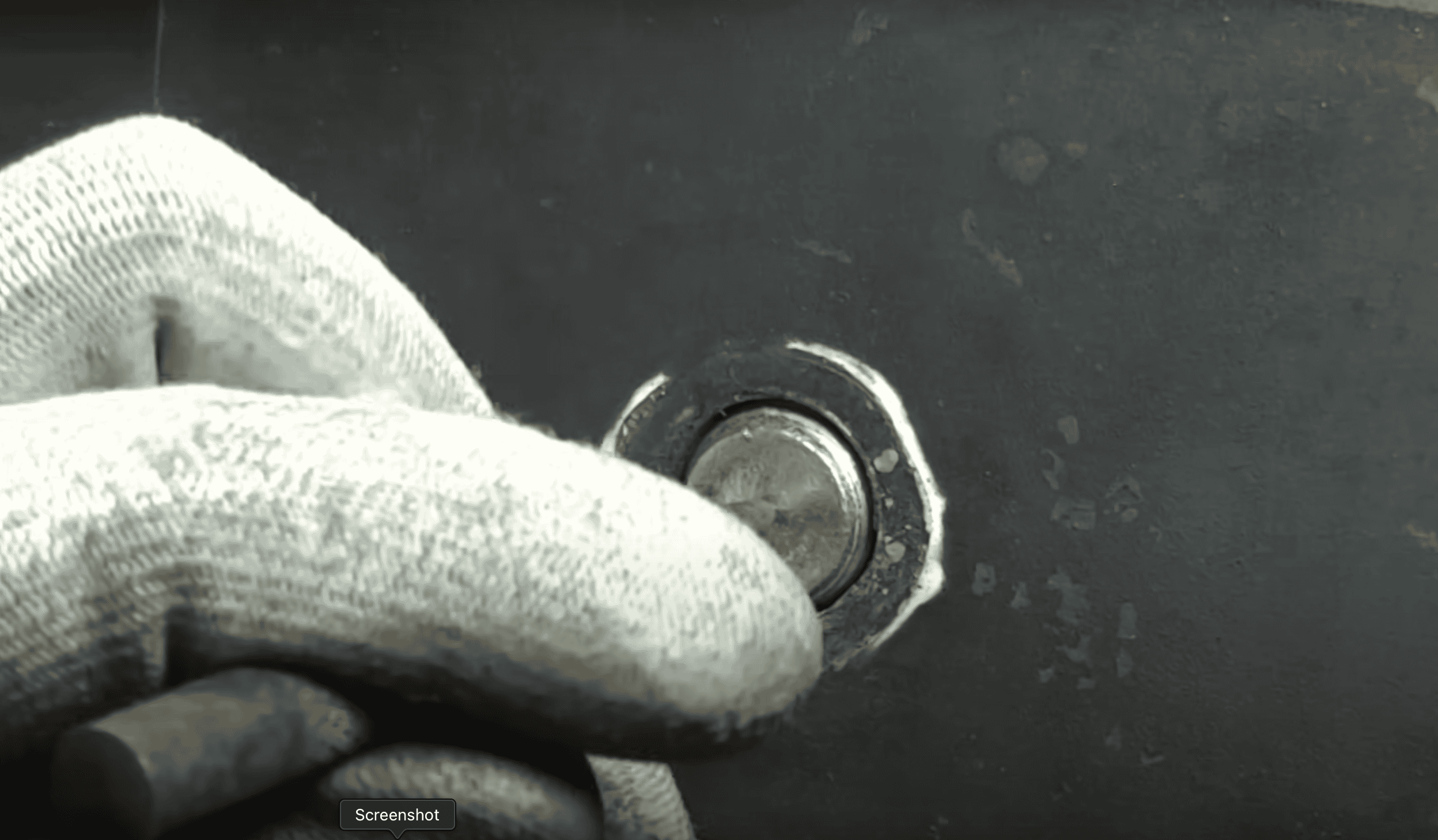

Step 2: Make the bolt surface flat and mark the center

The most critical element to succeed in this process is to drill precisely through the center of the bolt.

First, use a file or grinder to make the bolt’s surface as flat as possible to ensure you don’t mess up. Then, mark the center of the bolt with a center punch and a hammer. This notch will help your drill bit move in the right direction.

If you have an automatic center punch, your job will be much easier, and you won’t need a hammer.

Step 3: Drill through the bolt

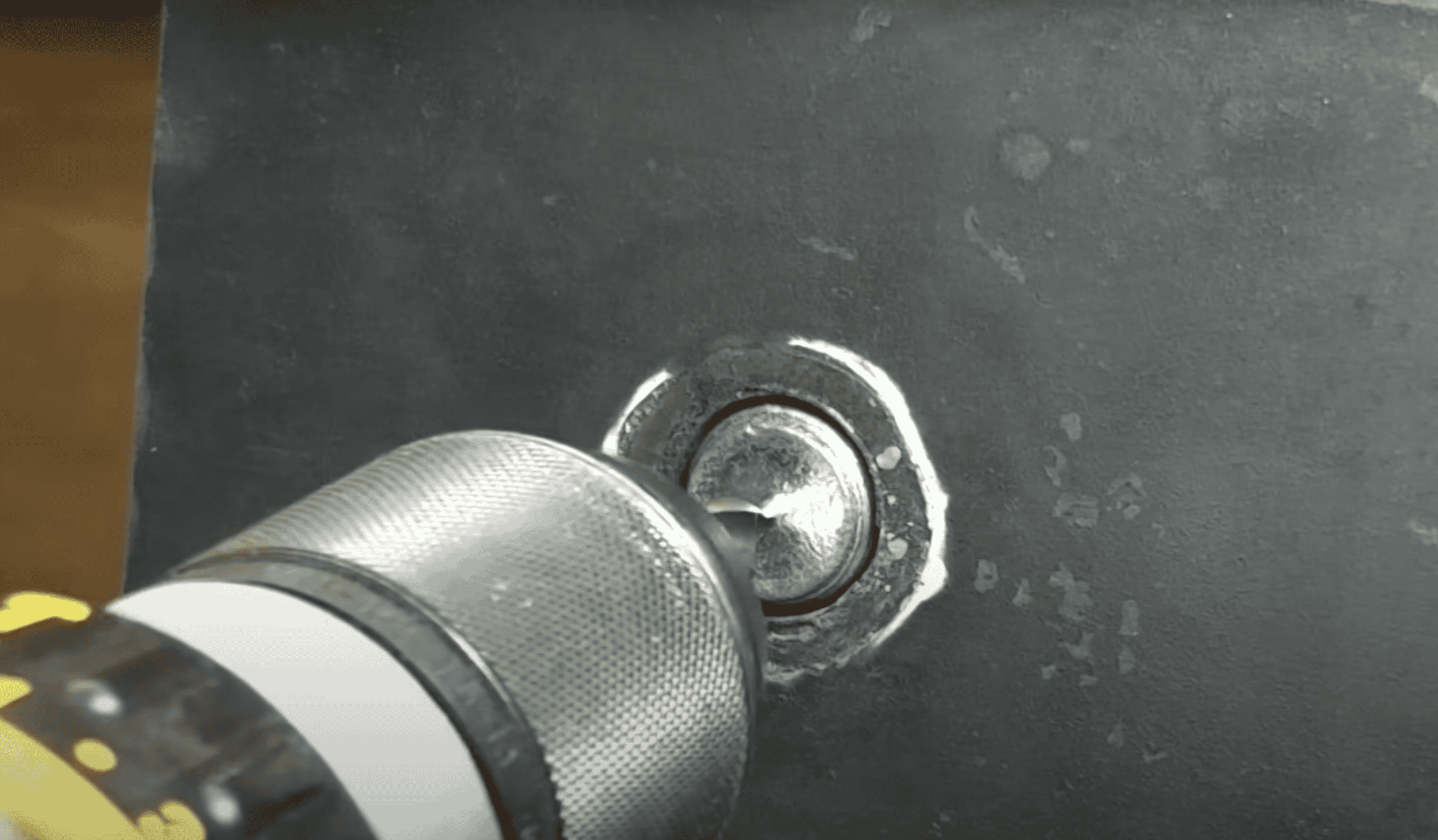

Now, we have moved to the final and foremost step of drilling the bolt out.

First, add some thread-cutting lubricant to the bolt. It will loosen the stuck bolt, especially if it is stuck due to corrosion; the lubricants will help. Keep it for a few minutes to allow it to work; meanwhile, we will move to the next phase.

Then, take a left-hand drill bit with a diameter less than the bolt you will extract. Fix the left-hand drill bit to the drill chuck and put the drill in reverse gear.

Place the drill bit on the center mark, and keep the drill straight. Drill slowly and put pressure on it. The drill bit will grab the bolt, and it will start to come loose as it turns.

Drill the broken bolt out slowly with a left-hand drill bit and reverse gear setup

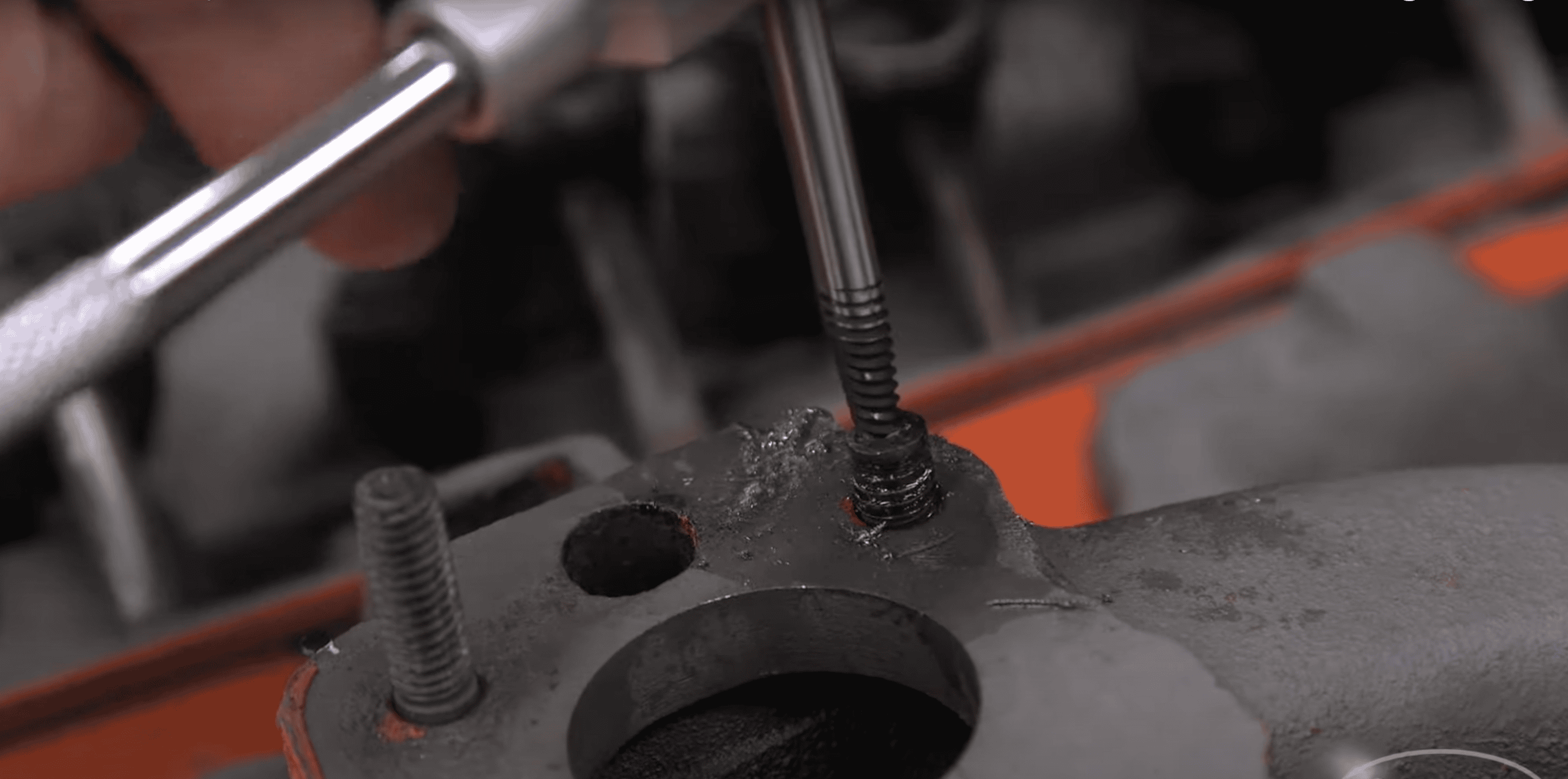

You will need one additional step if the bolt doesn’t come out even after drilling 2/3 of its length. You need to use a left hand bolt extractor or an Easyout here to remove the stuck bolt from its hole.

First, take out all the chips made of metal. Then turn the screw extractor to fit in the hole you made. Turn the extractor until the bolt is grabbed by it. If the extractor doesn’t hold the bolt, try a bigger one. Once the extractor holds the bolt, keep slowly turning the screw to get the bolt out.

Caution!

You don’t want to break a screw extractor inside the bolt. Hardened metal makes the screw extractors hard to drill. So, if it breaks inside the bolt hole, you are in deep shit!

You can watch the whole process in the below video.

Though the left-hand drill bits are rarely seen and used, they are handy in a few situations. Have you ever used one? Have you faced a broken bolt stuck situation? Let us know how you solve the problem in the comment below.