Tile is a very fragile and hard material, especially porcelain tile. If you can’t handle cutting operation, you may crack or be shattered the tile. Because of the molecular structure of the tile, you have to take precaution not to break the tile. There are very few materials harder than the porcelain tile.

If you want to know about diamond drill bit for porcelain tile read this article.

Tiles, especially porcelain tiles, are known for their hardness and fragility. If not handled correctly during cutting, they can crack or shatter. Their molecular structure requires precision, care, and the right tools to prevent damage. In this guide, we’ll explore whether you can cut tile with a circular saw, offer detailed steps, and provide essential numerical and statistical insights to enhance your tile-cutting experience.

What Makes Porcelain Tile So Tough?

Porcelain tile is one of the hardest construction materials, with a Mohs hardness rating of 6 to 7 out of 10. This hardness makes it more resistant to scratching but also more challenging to cut. Compared to standard ceramic tiles, porcelain tiles are denser and less porous, requiring specialized tools to make clean, precise cuts.

For comparison:

- Porcelain Tile Hardness (Mohs Scale): 6-7

- Standard Ceramic Tile Hardness (Mohs Scale): 5-6

Can a Circular Saw Cut Tile?

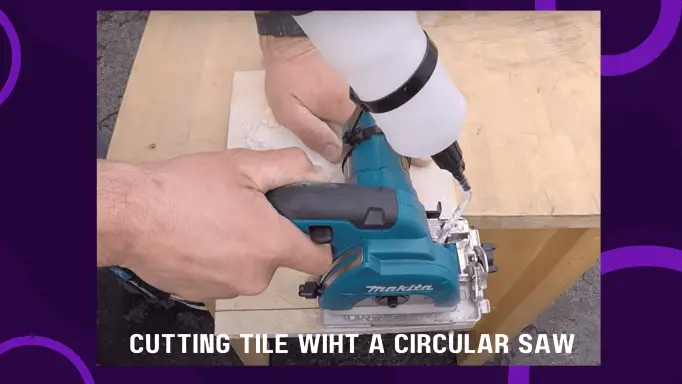

Yes, a circular saw can cut tile, but it’s not the most ideal tool for large-scale projects. It’s best suited for DIY projects or small jobs. To cut porcelain or ceramic tiles with a circular saw, you’ll need a diamond-coated masonry blade. This blade is essential because traditional blades are unable to handle the toughness of tile, especially porcelain.

Key Tools You Need:

- Circular Saw: A standard motorized hand-held tool

- Diamond-Coated Masonry Blade: Designed for cutting hard materials like porcelain and stone

- Water-Cooling Mechanism: Prevents overheating of the blade

- Respiratory Mask: Required if performing dry cutting to avoid inhaling dust particles

Why a Diamond-Coated Masonry Blade?

The cutting efficiency of a diamond-coated blade comes from the diamond particles embedded in the edge, which grind through the hard material. A diamond blade can cut through materials as tough as concrete and stone, making it perfect for tiles. Studies show that diamond-coated blades last 10-20 times longer than conventional abrasive blades when cutting tiles.

- Average Lifespan of a Diamond Blade: Up to 3,000 linear feet of cutting for tile materials

- Cutting Speed: Around 6-8 inches per minute for porcelain tiles (depending on thickness)

How to Cut Tiles Using a Circular Saw: Step-by-Step Guide

Step 1: Select the Right Blade and Prepare Your Equipment

Use a diamond-coated masonry blade for your circular saw. It’s crucial to ensure that the blade is designed for tile cutting. The water-cooling system, if available, will help keep the blade temperature down, reducing the risk of cracking the tile due to heat expansion.

- Average blade cost: $20-50 for a high-quality diamond-coated blade

- Water usage during cutting: Around 1 gallon per minute (depending on the water pump setup)

Step 2: Measure and Mark the Tile

Measure and clearly mark the tile where you intend to cut. It’s essential to make sure the mark is precise because tiles, especially porcelain, are unforgiving when it comes to mistakes. A 1/16-inch error can cause a tile to crack or shatter during cutting.

Step 3: Set the Saw and Begin Cutting

Position the tile on a sturdy surface, like a workbench, and begin cutting. Start slowly and apply even pressure. For best results, aim for a cutting speed of 1-2 inches per second. Applying too much force too quickly can lead to tile damage or even injury.

- Power required: Most circular saws operate at 120V and use around 1,500 watts of power. Ensure your setup can handle this capacity.

Step 4: Wet vs. Dry Cutting

If possible, use wet cutting. The water-cooling system not only cools the blade but also reduces dust. Wet cutting is recommended for cuts longer than 12 inches or for continuous cutting because it minimizes friction and blade wear.

- Temperature drop with water cooling: A 15-20% reduction in blade temperature can be expected, which can prevent cracking.

If you decide on dry cutting, ensure you have a high-efficiency particulate air (HEPA) filter mask to avoid inhaling fine dust particles. Tiles can release silica dust, which is hazardous when inhaled.

- *OSHA recommends a limit of 50 micrograms per cubic meter of air over an 8-hour shift to prevent lung damage from silica exposure.

Circular Saw vs. Tile Cutter

While a tile cutter is the ideal tool for cutting tiles, a circular saw can be a more economical option for small DIY projects. Tile cutters are specialized tools designed to score and snap tiles cleanly. However, their cost can range between $50 to $300 for basic models, while a circular saw with a diamond blade can perform adequately for small projects at a fraction of the cost.

Circular Saw (With Diamond Blade):

- Cost: $50 to $150 (depending on saw and blade quality)

- Best for: Small DIY projects, irregular cuts

Tile Cutter:

- Cost: $50 to $300 (depending on manual or motorized version)

- Best for: Large-scale tile jobs, straight-line cuts

Safety Tips:

Since circular saws are not traditionally designed for wet work, there’s a risk of electrical shock if water comes into contact with the motor. To prevent this, use a water-cooling system with a drip instead of a full immersion.

- Electrical Hazard: Wet cutting with a non-waterproof saw can increase the risk of shock by up to 50%. Always use proper safety gear like gloves, goggles, and masks.

Conclusion:

In conclusion, cutting tiles with a circular saw is possible, but it’s not without challenges. Using the right tools, including a diamond-coated masonry blade and a water-cooling mechanism, can make the process easier and safer. For small DIY projects, the circular saw can save you both money and time, especially when compared to purchasing or renting a tile cutter.

However, be mindful of the risks, particularly regarding wet cutting and electrical safety. Always use personal protective equipment (PPE) and take precautions to avoid injury.

By following the steps outlined and paying attention to the statistics and numerical details mentioned, you’ll be able to cut tiles with precision and efficiency using your circular saw. For larger projects, however, investing in a proper tile cutter might still be the best choice.

Pro Tip: Always double-check your measurements, and don’t rush the process. A 10-second pause before cutting can prevent costly mistakes!

To know details about cutting tiles by miter saw read this article.