Takeaways:

- Hand saws are versatile tools for cutting wood, metal, drywall, and plastic.

- Saw performance depends largely on teeth per inch (TPI), where lower TPI yields faster cuts and higher TPI delivers smoother finishes.

- Different saw types are better suited for specific tasks, such as coping saws for detailed work and rip saws for large wood cuts.

Hand saws are essential tools for various DIY and professional projects. Whether you’re trimming a branch, cutting through metal, or making fine furniture, choosing the right type of hand saw is critical. In this guide, we’ll explore different types of hand saws and their specific uses, complete with essential statistics and tips to help you make the best choice.

The Basics of Hand Saws

Saw blades are characterized by their Teeth Per Inch (TPI). The lower the TPI, the quicker the cut but with a rougher finish. Conversely, higher TPI blades produce finer, smoother cuts. For example:

- 2–8 TPI: Fast cuts, rough finish (ideal for heavy-duty wood cuts)

- 9–14 TPI: General-purpose, moderate finish

- 15–32 TPI: Precision cuts, fine finish (best for metals and detailed work)

Common Hand Saw Uses

Hand saws can be used for a variety of tasks, including:

- Woodworking

- Metalworking

- Drywall Cutting

- Plastic Cutting

- Furniture Making

Woodworking with Hand Saws

Hand saws for woodworking come in many forms, each designed for specific tasks like shaping wood, trimming branches, or making detailed cuts.

| Type of Saw | Use |

|---|---|

| Backsaw | Precise cuts, such as joinery |

| Coping Saw | Cutting intricate shapes and curves |

| Rip-Cut Saw | Cutting wood along the grain |

| Crosscut Saw | Cutting wood across the grain |

- Backsaw: Known for precision, this saw is ideal for dovetailing and tenon cuts.

- Coping Saw: Excellent for fine woodworking and moldings; it allows intricate inside cuts.

- Rip-Cut Saw: Efficient for cutting along the wood grain, typically used for rough framing and resizing boards.

- Crosscut Saw: Designed for cutting across the grain, making it perfect for trimming lumber.

Woodworking Statistics:

- Average Blade Length: 12–26 inches.

- TPI Range: 4–12 TPI for general woodworking.

Metalworking with Hand Saws

Metalworking often requires saws that can handle harder, denser materials.

| Type of Saw | Use |

|---|---|

| Hacksaw | Cutting metal pipes and sheets |

| Keyhole Saw | Piercing holes in metal sheets |

- Hacksaw: Known for versatility, with blade lengths ranging from 10 to 12 inches. TPI typically ranges between 14 and 32, allowing it to cut through thin metal pipes and thick iron bars.

- Keyhole Saw: Great for piercing and cutting small holes in metal sheets, drywall, or plywood.

Metalworking Statistics:

- Blade TPI: 14–32 TPI for metal cuts.

- Average Blade Thickness: 0.025 inches.

Drywall Cutting

For cutting holes in drywall or trimming boards, the following saws are commonly used:

| Type of Saw | Use |

|---|---|

| Keyhole Saw | Piercing holes in drywall |

| Wallboard Saw | Cutting drywall panels |

- Keyhole Saw: Perfect for making holes in walls for outlets or fixtures.

- Wallboard Saw: Used for cutting drywall panels quickly.

Drywall Cutting Statistics:

- Blade Length: 6–10 inches for wallboard saws.

- TPI Range: 5–8 TPI for quick drywall cuts.

Plastic Cutting

Cutting plastic requires precision and sometimes flexibility.

| Type of Saw | Use |

|---|---|

| Pull Saw | For straight cuts in plastic |

| Fret Saw | For intricate plastic cuts |

| Hacksaw | For larger plastic pipes |

- Pull Saw: Excellent for straight cuts in plastic materials.

- Fret Saw: Great for detailed cuts in thin plastic sheets.

- Hacksaw: Handles thicker plastic materials, like PVC pipes.

Plastic Cutting Statistics:

- Blade TPI: 12–24 TPI for fine plastic cuts.

- Blade Length: 10–12 inches for hacksaws.

Furniture Making

Crafting furniture often requires fine, detailed cuts with high precision.

| Type of Saw | Use |

|---|---|

| Rip Saw | For large furniture cuts |

| Crosscut Saw | For intricate woodworking |

| Dovetail Saw | For detailed furniture joinery |

| Coping Saw | For curves and detailed shaping |

- Rip Saw: Ideal for cutting long planks for furniture frames.

- Dovetail Saw: Essential for making joints for shelves and drawers.

Furniture Making Statistics:

- Blade TPI: 8–12 TPI for rough cuts, 14+ TPI for fine detail work.

Common Types of Hand Saws

Here’s a breakdown of other common hand saws used in various projects:

- Hacksaw: Versatile saw for cutting metal and plastic.

- Coping Saw: Ideal for intricate cuts and inside curves.

- Bow Saw: Best for trimming trees and logs.

- Rip-Cut Saw: Perfect for cutting wood along the grain.

- Crosscut Saw: Designed to cut across the grain of wood.

Each of these saws has unique advantages, so it’s essential to choose the right one for the task at hand.

Common Types of Hand Saws: A Detailed Guide

Hand saws are versatile, manual tools that have been used for centuries in woodworking, metalworking, and other tasks requiring precision cuts. Understanding the different types of hand saws and their uses is essential for selecting the right tool for your project. Below is a comprehensive guide to some of the most common types of hand saws, including detailed descriptions, their specific applications, and numerical data to help you make an informed decision.

1. Rip-Cut Saw

Usage:

- Primarily used for cutting wood along the grain (lengthwise).

- Best suited for tasks like splitting logs or planks.

Key Features:

- TPI (Teeth Per Inch): Typically 5 to 7 TPI. Lower TPI means faster cutting but rougher finishes.

- Tooth Shape: Large, angled teeth with alternating left and right bends.

- Cutting Action: Works on the push stroke, which allows the saw to dig into the wood and remove material efficiently.

Use Cases:

- Ideal for woodworking projects like splitting lumber or making furniture pieces where cutting along the grain is required.

- Often considered an all-purpose saw for woodworking.

2. Crosscut Saw

Usage:

- Designed to cut across the wood grain, making it ideal for trimming branches or cutting lumber.

Key Features:

- TPI (Teeth Per Inch): Ranges between 10 and 12 TPI for one-person saws, while two-person saws typically have 1 TPI for heavy-duty tasks.

- Tooth Shape: Teeth are angled to produce clean, smooth cuts across the grain.

- Blade Length: One-person saws have shorter blades, while two-person saws can range from 4 to 8 feet in length.

Use Cases:

- Excellent for cutting rough wood surfaces, trimming large tree branches, or preparing firewood.

3. Hacksaw

Usage:

- Primarily used for cutting metal pipes and other metal materials, though it can also cut plastic and wood.

Key Features:

- Blade Length: 10 to 12 inches in length and 7/16” to 9/16” wide.

- TPI (Teeth Per Inch): Typically 14 to 32 TPI. Higher TPI is used for finer, more precise cuts, while lower TPI is for thicker metals.

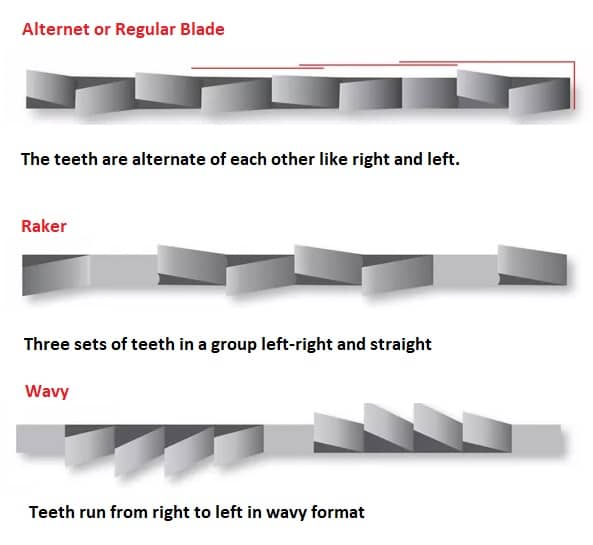

- Blade Types:

- Alternate (Regular): Ideal for cutting soft metals like aluminum or tin.

- Raker: Suitable for standard metal pipes.

- Wavy: Produces smoother cuts and is suitable for cutting sheet metal.

Use Cases:

- Widely used in metalworking to cut pipes, rods, or thin metal sheets.

- Also used for DIY projects involving plastic cutting.

4. Coping Saw

Usage:

- Best for intricate cuts in thin materials, making it ideal for woodworking tasks like cutting molding or trim work.

Key Features:

- Blade Length: Typically 6-3/4 inches.

- TPI (Teeth Per Inch): 10 to 32 TPI, depending on the material being cut.

- Frame: U-shaped frame with tension screws for blade adjustment.

- Cutting Action: Suitable for both external and internal cuts, allowing for precision in corners and angles.

Use Cases:

- Used for creating curved shapes, back-beveled cuts, and precise joints in woodworking.

- Ideal for cutting trim, crown molding, and aluminum pipes.

5. Bow Saw

Usage:

- Ideal for outdoor tasks like pruning trees, cutting logs, and trimming shrubs.

Key Features:

- Blade Length: Varies based on the saw type. Longer blades with larger teeth are used for rough cuts, while shorter blades with smaller teeth are used for finer cuts.

- TPI (Teeth Per Inch): Ranges from 3.5 to 11 TPI depending on the type of cutting required.

- 3.5 to 5 TPI: Suitable for rough cuts.

- 6 to 8 TPI: General-purpose cutting.

- 9 to 11 TPI: Fine carpentry work.

- 12+ TPI: Used for very fine cuts.

Use Cases:

- Perfect for landscaping tasks, including cutting through tree trunks, branches, and logs.

- Can also be used for rough carpentry work.

6. Keyhole Saw

Usage:

- Specialized saw for cutting small, intricate holes in drywall, wood, and plastic.

Key Features:

- Blade Length: Typically short, with a pointed tip for piercing through materials.

- TPI (Teeth Per Inch): 6 to 15 TPI, depending on the material being cut.

- Cutting Action: Designed for push-and-pull strokes to create precise holes or openings.

Use Cases:

- Used in construction and home renovation to make holes in walls for fixtures, outlets, or switches.

7. Japanese Saw

Usage:

- Known for its pull-cutting action, which makes it easier to use and results in smoother cuts.

Key Features:

- TPI (Teeth Per Inch): 8 to 12 TPI, depending on the model and use.

- Cutting Action: Works on the pull stroke, which makes it different from traditional push saws.

- Blade Types: Comes in various forms such as dovetail saws, which are ideal for fine woodworking.

Use Cases:

- Ideal for woodworking tasks that require precision and a smooth finish, such as cutting joints or fine details in furniture making.

8. Backsaw

Usage:

- Designed for precision cuts, often used in woodworking projects requiring fine detailing.

Key Features:

- TPI (Teeth Per Inch): 12 to 16 TPI, which allows for fine, smooth cuts.

- Cutting Action: Works on a push stroke, producing precise cuts with minimal splintering.

- Reinforced Back: A rigid spine helps maintain straight, controlled cuts.

Use Cases:

- Commonly used for dovetail cuts, tenons, and other precise joinery tasks.

- Frequently used in carpentry and fine woodworking projects.

9. Fret Saw

Usage:

- A specialized saw for intricate, fine cuts in wood or metal, similar to a coping saw but with a thinner blade.

Key Features:

- Blade Length: Extremely thin blades, usually replaceable.

- TPI (Teeth Per Inch): Can range from 15 to 32 TPI, depending on the material being cut.

- Cutting Action: Ideal for tight curves and intricate details.

Use Cases:

- Used for cutting delicate patterns and curves in wood, metal, or plastic.

- Perfect for detailed crafts and fine woodworking.

Conclusion: Choosing the right hand saw depends on your project’s requirements. Consider the material, cutting type, and finish you desire before selecting a saw. With this guide, you’re equipped to make an informed decision for any cutting task—be it woodworking, metalworking, or DIY projects.

| Type of blade | Construction | Usages |

|---|---|---|

| Alternate/Regular | The teeth are alternate of each other like right and left. | 1. For quick removal of iron-free softer metals like aluminium or tin, PVC, conduit, cut fibreglass 2. Rough cut less finishing 3. Don’t use heavy metal |

| Raker | Three sets of teeth in a group left-right and straight | Thick or standard metal pipes |

| Wavy | Teeth run from right to left in the wavy format | 1. Smooth cut in hard metal, useful for cutting sheet metal 2. Not use in hard metal 3. Less noise and vibration during cutting |

Coping Saw

Coping saw as like hack saw and in bigger bow saw category. The purpose of U shaped saw is basically coping. The saw also used both external and internal cutting. Coping saw blade is thin and shorter compare to other bow saw typically 6-3/4 inch. The blade is attached in a lighter steel frame locked on both ends by 2 tension screws. Teeth range between 10 to 32 TPI.

Coping saw use to thin materials such as trim work, cut wooden molding, aluminum pipework. Coping tiny blades capable to cut back-beveled to create precise joints. This saw should not use for more than 1 inch thickness job.

| Type of Saw | Type of cutting |

|---|---|

| cut through a hole or even a cutout | |

| back-beveled cut | |

| Coping Saw | back-cut curves and create precise joints |

| inside corner joints when installing trim | |

| angels, corner, crown molding |

Bow Saw

There are 2 different types of bow saw, straight toothed and raker toothed. The frame is fixed length but blade tension is adjustable by tension screw. The longer the blade have bigger teeth and the shorter saw have smaller teeth. Bigger and fewer teeth can give you faster cut but rough but more teeth less cutting ability but fine cutting and more finishing.

Bow saw is used for outdoor crosscut the trimming trees, pruning, sawing logs, but may be used for other rough cuts as well.

| Type of teeth | Type of cutting |

| long blade with numerous transverse teeth | remove material when pushing and pulling |

| 3.5 to 5 TPI | suitable for rough cutting |

| 6 to 8 TPI | all-round cutting |

| 9 to 11 TPI | fine carpentry |

| 12 and more TPI | suitable for very fine carpentry |