Keynotes and Takeaways

- Circular saw blades undergo a hardening process to enhance their strength, durability, and performance.

- Not all circular saw blades are hardened equally; the method and degree of hardening vary based on the blade type and material.

- Hardened blades provide longer cutting life and resistance to wear, but the hardening method impacts their cost and suitability for specific tasks.

- Table comparison included to showcase differences between hardened and non-hardened blades.

- FAQs section answers common questions about circular saw blade hardening, types, and uses.

Introduction

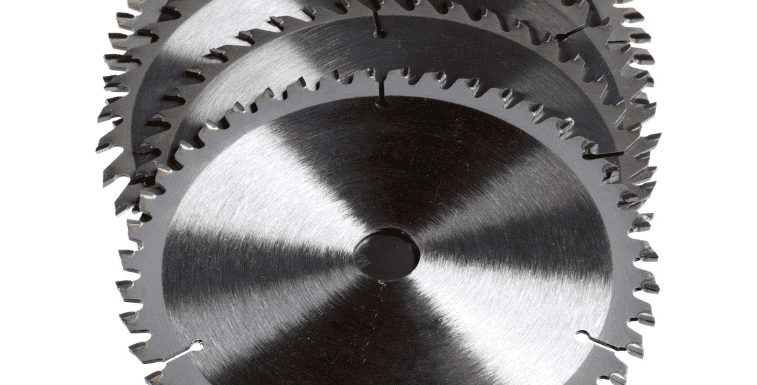

Have you ever wondered why some circular saw blades last longer, cut smoother, and seem more resistant to wear and tear than others? If you’re experiencing blade wear or inconsistency in performance, you might be asking: Are circular saw blades hardened?

The hardening process is a crucial factor in determining a saw blade’s effectiveness. But not all blades are created equal, and understanding the specifics of hardening can help you select the best tool for your needs. In this article, we’ll explore everything you need to know about whether circular saw blades are hardened, how this process works, and how it impacts blade performance.

What Does Hardening Mean for Circular Saw Blades?

The term hardening refers to a heat treatment process where the metal of a blade is strengthened by heating it to high temperatures and then cooling it rapidly. This process increases the hardness and durability of the blade, making it more resistant to wear and tear during cutting tasks.

How Does Hardening Work?

Hardening typically involves heating the blade steel to a temperature between 800°C to 1,000°C (1,472°F to 1,832°F), followed by rapid cooling through quenching in oil or water. This cooling locks the metal structure into a hardened form, often followed by a process called tempering, which slightly reduces the hardness to make the material tougher and less brittle.

Benefits of Hardened Circular Saw Blades

Hardened circular saw blades provide several key advantages over non-hardened ones. Here’s a detailed breakdown of why these blades are more efficient and reliable for a variety of cutting tasks:

1. Extended Durability

Hardened blades are far more durable, capable of withstanding continuous use without significant wear. The hardening process ensures the blade retains its sharpness longer, especially when cutting hard materials like metal or hardwood.

2. Improved Precision

Blades that have undergone the hardening process maintain a more consistent and precise cut due to the enhanced stability and reduced chances of warping. This makes them ideal for professional-grade applications where precision is essential.

3. Resistance to Heat and Friction

During cutting, the blade generates heat and friction. Hardened blades are designed to better withstand these conditions, allowing for smoother cuts and less frequent overheating.

Comparison: Hardened vs. Non-Hardened Circular Saw Blades

| Feature | Hardened Circular Saw Blades | Non-Hardened Circular Saw Blades |

|---|---|---|

| Durability | High, lasts longer | Lower, wears out faster |

| Cutting Precision | Excellent, stable cuts | Less precise, prone to warping |

| Cost | More expensive | More affordable |

| Heat Resistance | High, less prone to overheating | Low, more affected by heat |

| Ideal Use | Professional, heavy-duty tasks | Light or occasional DIY use |

The above table showcases the clear differences between hardened and non-hardened blades. While hardened blades offer superior durability and precision, they come at a higher cost. Non-hardened blades may be more affordable, but they lack the long-lasting performance required for demanding tasks.

How Are Circular Saw Blades Hardened?

There are several methods used to harden circular saw blades, each with varying levels of efficiency and cost. Let’s explore the most common methods:

1. Heat Treatment Hardening

This is the most common process used for hardening circular saw blades. The blade is heated to extreme temperatures and then cooled rapidly in a quenching solution. This process makes the steel harder and more resistant to wear.

2. Induction Hardening

Induction hardening is a more localized process where only the teeth or edges of the blade are heated and hardened. This allows the body of the blade to remain flexible while ensuring that the cutting edges are extremely durable.

3. Case Hardening

This method hardens only the surface of the blade, leaving the inner core softer. It is commonly used for budget-friendly blades that require a hardened outer shell to resist wear but don’t need the high strength of fully hardened blades.

Statistics: The Impact of Hardening on Blade Performance

Research and studies on tool performance have shown that hardening significantly extends the life of cutting tools like circular saw blades. Here are some key statistics:

- Hardened blades last up to 50% longer than non-hardened counterparts in high-use scenarios.

- Precision of cut improves by approximately 30% when using a hardened blade, especially on materials like metal and hardwood.

- Induction-hardened blades show a reduction in wear by 40%, compared to blades that haven’t undergone any hardening treatment.

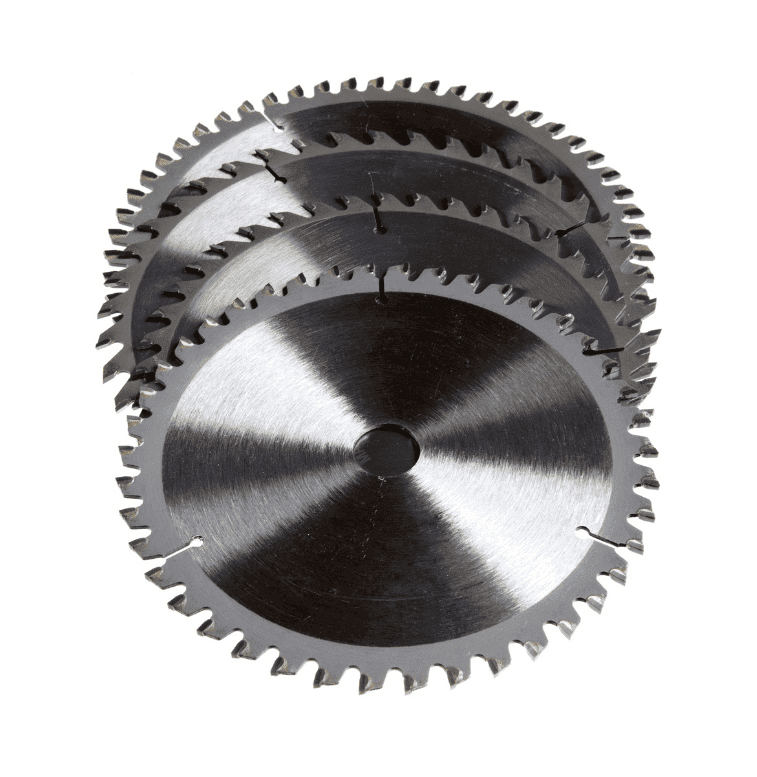

Which Circular Saw Blades Are Hardened?

Not all circular saw blades are hardened. The type of blade and its intended use will determine whether or not it has undergone a hardening process. Here’s a quick breakdown:

1. Carbide-Tipped Blades

Most carbide-tipped blades are hardened using induction or heat treatment to ensure that they can handle tough materials like steel and hardwood.

2. Metal Cutting Blades

Metal cutting circular saw blades often undergo full heat treatment hardening to withstand the extreme heat generated during use. These blades are designed for cutting aluminum, steel, and other metals.

3. Wood Cutting Blades

Wood cutting blades may or may not be hardened, depending on the quality. Cheaper blades often skip the hardening process, while professional-grade ones go through heat treatment for enhanced durability.

When Should You Use Hardened Circular Saw Blades?

Hardened circular saw blades aren’t necessary for every task, but they are a must for certain applications. If you frequently work with tough materials, such as metal or hardwood, using a hardened blade is essential to ensure both performance and longevity.

1. Professional Applications

For professionals who rely on precision and efficiency, hardened blades are a top choice. Whether it’s metalworking or detailed woodworking, the durability and sharpness retention of hardened blades make them a sound investment.

2. High-Volume Tasks

If you regularly cut through dense materials, a hardened blade will pay off in the long run. These blades last significantly longer than their non-hardened counterparts, reducing the need for frequent replacements.

3. DIY Projects

While hobbyists and DIY enthusiasts may not always need hardened blades, certain projects—such as installing flooring or cutting metal sheets—require a blade that can handle tougher conditions.

Conclusion

To sum it up, yes, circular saw blades are hardened, and this hardening process plays a critical role in enhancing their performance. Whether you’re working on a simple DIY project or tackling professional-grade tasks, understanding the differences between hardened and non-hardened blades will help you make the right decision.

Hardened blades offer superior durability, precision, and resistance to wear, but they come at a higher cost. When choosing a circular saw blade, it’s essential to consider your specific needs, the materials you’re cutting, and the longevity you’re aiming for.

Ready to upgrade your cutting tools? Explore more tips and tricks on choosing the right blades by reading more blog posts from MAKELIFE EASY APPS.

FAQs

- Are all circular saw blades hardened?

No, not all circular saw blades are hardened. The level of hardening depends on the type of blade and its intended use. - Can I use a non-hardened blade for cutting metal?

It’s not recommended to use non-hardened blades for metal cutting as they wear out quickly and may not offer precise cuts. - Why are hardened blades more expensive?

Hardened blades undergo additional treatment processes, which increase their durability and performance, leading to higher production costs. - How do I know if a blade is hardened?

Manufacturers usually indicate if a blade is hardened. You can check the product specifications or labels for information on heat treatment or hardening. - Is induction hardening better than heat treatment?

Induction hardening focuses on specific areas, such as the teeth, offering better precision. Heat treatment hardens the entire blade, making it suitable for tougher materials. - What’s the difference between a hardened blade and a carbide-tipped blade?

Hardened blades refer to the steel being strengthened through heat treatment, while carbide-tipped blades have hard carbide edges that offer enhanced cutting efficiency.